Packing is an important process in the biscuit production process. It protects against moisture and dust, and extends the shelf life of biscuits. The most commonly used packaging method is the pillow pack.

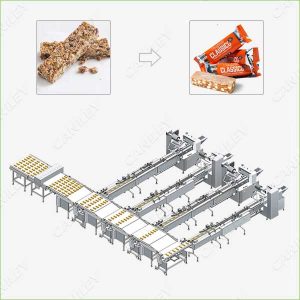

Bakery Biscuit Packing Machine Work Process:

Depending on the biscuit type, the packaging film is pre-dimensioned and fed out through feed rollers to form cylindrical bags in the bag former. Then, both ends of the film are folded, and heat and pressure are applied to both ends of the film at the center sealing portion of the pillow pack machine, and thermal bonding (heat sealing) is performed. Through the supply conveyor belt set at the front end (supply part) of the bag former, the biscuits are continuously inserted into the tubular film at regular intervals. The pillow pack machine presses the conveyor belt up and down, the biscuits in the tubular film continue to advance at a certain interval. The biscuits and the middle film of the biscuits are heated by the end sealing device, and are cut by the cutter while being pressurized and heat sealed, thus completing the packaging process.

Bakery Biscuit Packing Machine Constitute:

The bakery biscuit packing machine adopts frequency conversion speed regulation, Microcomputer controller (WDK) control system, PlD digital display intelligent temperature controller, Photoelectric detection two-way tracking system, Small screen power display system and circuit protection system. It realizes stepless speed change, automatic tracking of cut points, accurate temperature control, high packaging precision, intuitive display, and safety and security.

Application:

In general, pillow pack machines are often used for the following types of products:

- At present, most candy, chocolate, biscuits, bread, and other manufacturers use pillow packaging.

- Disposable toothpaste toothbrush and chopsticks. The basic structure of this type of product is similar to that of candy packaging, the difference is the difference in packaging materials. Some foods are packaged with PE film, and some are composite films, while for daily necessities, the requirements for materials are not so strict.

- Industrial supplies. For example, semi-finished toys and even some hardware products are packaged in pillow-type bags.

Biscuit Packing Machine Features:

- Double frequency converter control, the bag length can be set and cut immediately, no need to adjust the idling, one step, saving time and film.

- Text-type man-machine interface, the parameter setting is convenient and quick.

- Fault self-diagnosis function, fault display is clear at a glance.

- High-sensitivity photoelectric eye color tracking makes the sealing and cutting position more accurate.

- Temperature-independent PID control, is better suitable for packaging films of various materials.

- The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

- Freely configurable on the touch screen, multi-zone temperature control, excellent packaging and high-quality sealing.

According to the customer’s packaging requirements, we can also increase the material sorting line to reduce the time spent by manual feeding.

Reviews

There are no reviews yet.